STRAWORKS WALL SYSTEM NO.1

Quality construction since 2004

SWS No.1 — a Pre-Engineered Straw Wall System

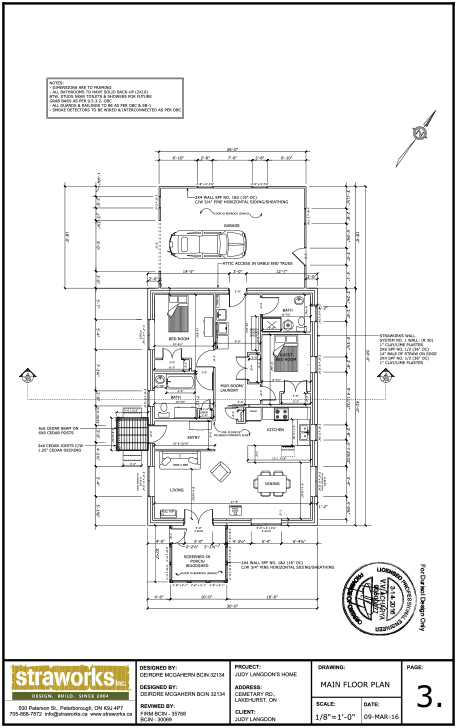

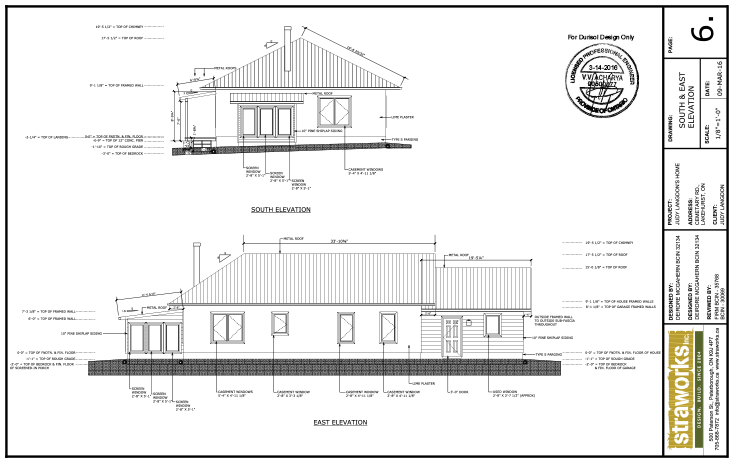

Straworks Inc. has its own pre-engineered wall system for one-storey straw bale buildings that are less than 2160 square feet: Straworks Wall System No. 1 (SWS No.1). These are some of our recent projects:

SWS No.1 allows Straworks to bypass a time-intensive step for obtaining building permits for structures that meet its parameters. Straw bale construction is not recognized by the Ontario Building Code, which means that every set of plans typically needs to be stamped by a structural engineer in order to obtain a building permit. But by designing the building according to the SWS No.1 system, and by attaching the system drawings to the building permit application, the building is engineered and permitted without a custom stamp. The plans don’t end up spending several weeks on an engineer’s desk and the cost of using the SWS No.1 is less than an the cost of an engineer’s stamp!

Parameters of the Straworks Wall System No. 1

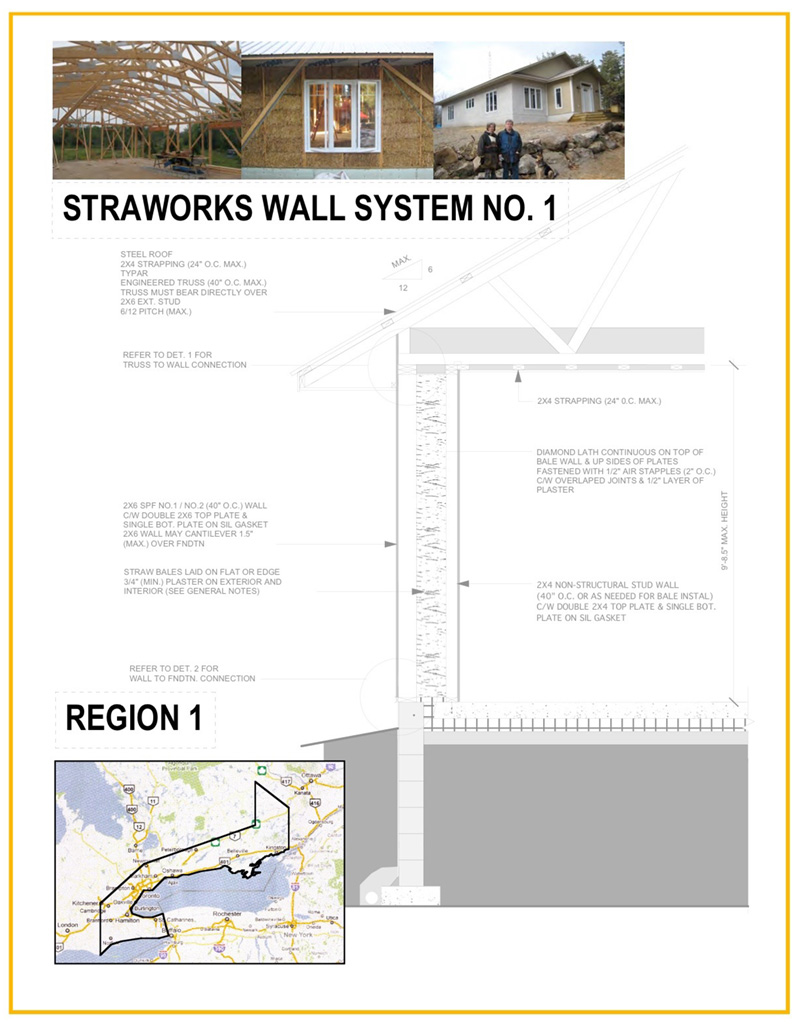

- One storey in height

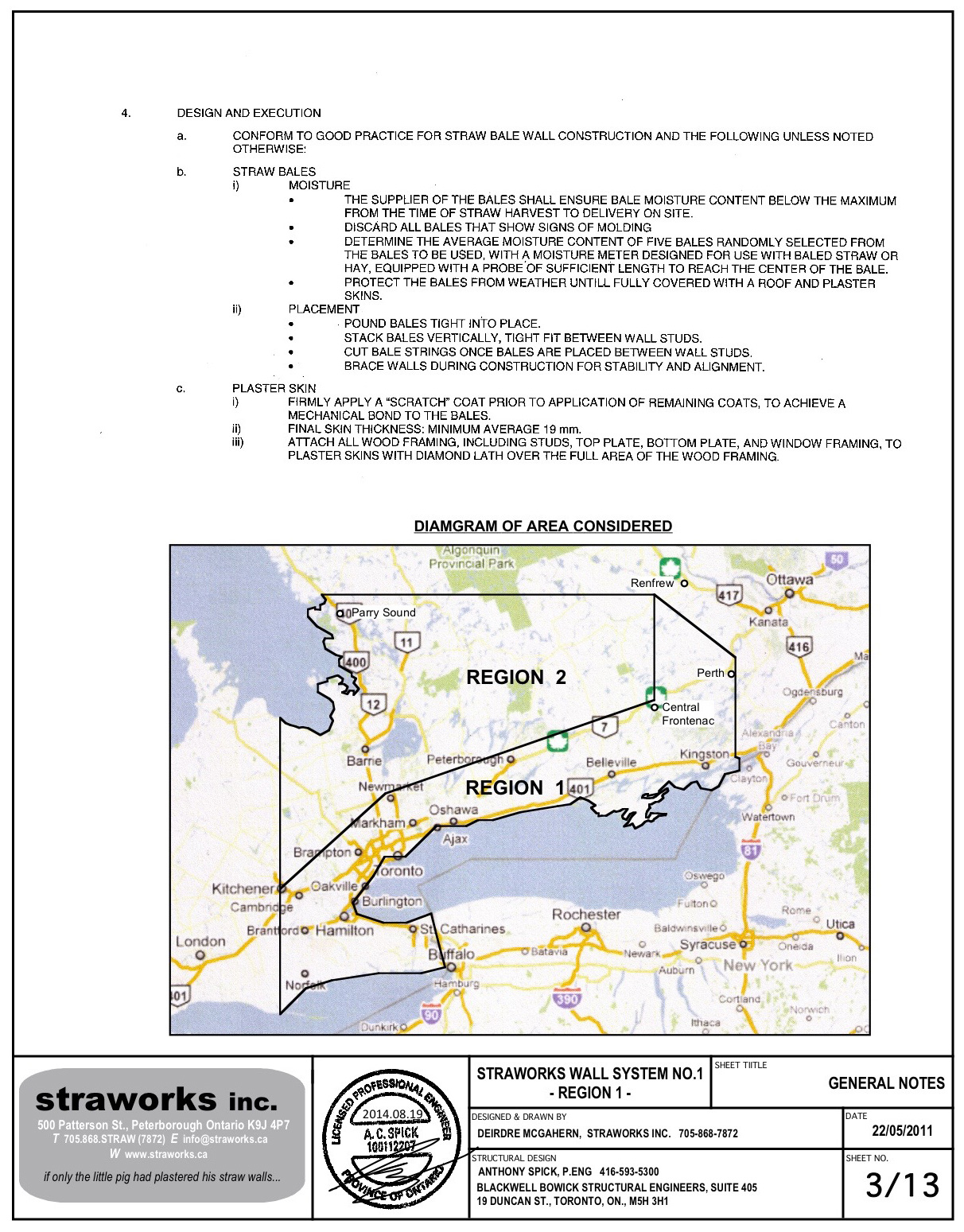

- Within the geographic area outlined on the map of Ontario below

- Measure 36′-0″ wide x 60′- 0″ long or less

- Roof pitch of 6/12 or less

Background & Description

Straworks Wall System No. 1 was designed by Deirdre McGahern and Anthony Spick (P.Eng) of Blackwell Structural Engineers in 2009. It is based on their collective experience of designing, engineering and building many different types of straw bale buildings, and being driven to a standard system that is designed for ease of construction, conservation of materials, and to lower the engineering bill for people looking to build modest and affordable straw bale homes.

Straworks Wall System No.1 is a hybrid system that uses bale dimensions as the framing module. The framing system is designed to maximize ease of bale installation and thermal performance. The length and width of a building are divisible by 3 ft. (a bale length). The height of the walls corresponds to bales stacked 5, 6 or 7 courses high. Window sizes and placement are designed so bales fit around them. This design saves hours of time and energy on-site spent modifying bales to fit a frame that wasn’t designed with them in mind. Furthermore, by avoiding cutting and notching bales we keep them whole and allow them to do what they do best: insulate our walls.